Design and prototyping

Let us help you validate your project and provide recommendations on how to optimize your design. We can develop different pattern types to ensure that your project is manufactured quickly and at the lowest cost possible. Regardless of the dimension or specificities of the part to be produced, we can help! From new and simple projects to the most complex casting design you can think of, we’ve got you covered.

Additional services

Paber has built a solid track record as a trustworthy aluminum casting partner for a wide variety of other services:

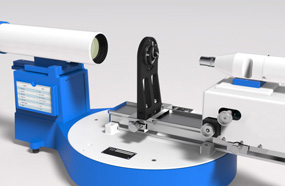

Machining

Whether you need CNC 3, 4 and 5 axis or conventional machining, our in-house machine shop will provide the highest level of accuracy and quality. Part sizes are not an issue: our equipment and machining partners can provide 3, 4 and 5 axis machining on castings of up to 8 feet in diameter.

Heat treatments

We offer in-house heat treatments of T4, T51, T6, T71, T77, and more. Using the newest technologies and providing the highest accuracy possible, the mechanical properties of your products will be optimized.

Painting

Painting on aluminum castings is an art! Our paint partners understand the process very well and know exactly how to achieve the final surface finish you want for your product, which can be powder coating, liquid coating, and e-coating. We take into account esthetics, textures, smooth areas, masked areas, stamping and more.

X-Ray

Using the biggest North American real-time X-Ray machine, Paber is able to certify your products as Level 1, 2 or 3 in X-Ray standards.

Surface treatments

We offer anodized, hard anodized, Chromate, Iridite, Teflon casting and more—all based on the ROHS standard.

Surface finishing

Several finishing processes are available to achieve your product requests: wheelabrating, tumbling, sand blasting, shot blasting with glass beads, aluminum oxide, polishing, Scotch-Brite, and many more.

Pattern fabrication

Molds, patterns and core boxes design and fabrication are made in-house and with our pattern shop partners, along with maintenance, repair and modifications.

Impregnation

Never underestimate the importance of impregnation for the long-term durability of your components! Paber offers seamless casting impregnation, sealing porosities for good and ensuring the prospering curing of paint or other finishes. This helps to reduce moisture, mitigate internal corrosion, and improve the overall quality of the parts we produce.

Hot Isostatic Pressing (HIP)

Paber uses HIP, which bonds materials together in cast components, to eliminate internal porosity and improve the useful life of your cast components. Paber’s HIP process improves casting quality, maximizes cost effectiveness and reduces scrap rates.

If you are looking for premium aluminum casting services, for either turnkey or customized projects, you can depend on Paber. Let us develop your products for assembly or final use! Contact us today for more information.