Green sand casting

This is the perfect process for prototyping and production of mid-range quantities. Green sand casting provides the flexibility, low cost, efficiency and quick turnaround times for your most pressing needs. Several tooling types are also available. We offer small and large production capacities for different types of cones (shell cores, CO2 and no bake). Remember! Green sand casting is still up-to-date for your production. You can even make design changes and modifications to your product without necessarily breaking the bank!

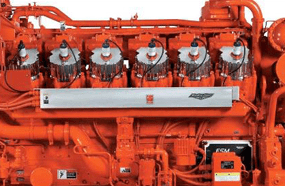

No-bake process

Our no-bake process is most suitable for esthetic finishes, large-sized parts, complex coring and tight casting tolerances. The no-bake process also allows for better quality and precision. Are you looking for over-molding or the integration of tubing, studs, inserts or other types of integrations? We have been doing it for years—with impressive results.

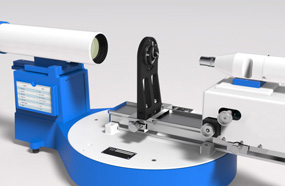

Permanent molding

From a few ounces to 100 pounds, our permanent molding process can provide a production capacity of up to 30 000 units per year with high casting efficency. This is the ideal process to manufacture low-cost products with the same high-quality levels and control that only Paber can guarantee. And don’t hesitate to bring us your most complex projects: Paber can handle everything from coning inserts, stud integration, large-sized parts, and more!

Available alloys

Paber offers the following alloys: 206, 319, A356, 413, 535, 713, Duralcan 20% and 30% and many more!

If you are looking for premium aluminum casting services, for either turnkey or customized projects, you can depend on Paber. Contact us today for more information.